|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

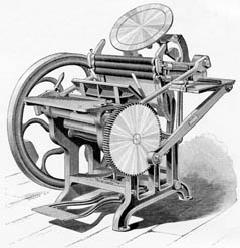

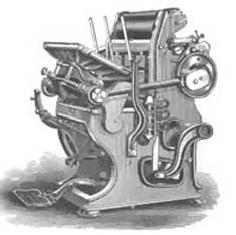

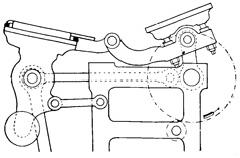

Gordon with 'bolt-on' cylinder style ink table distribution

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

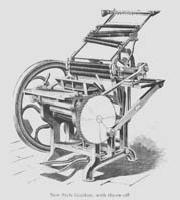

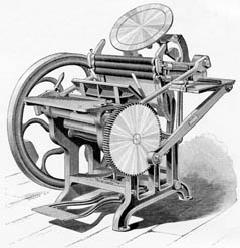

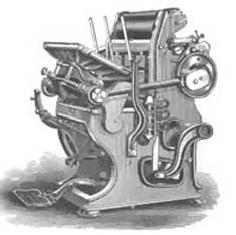

"Franklin New Style" Press 1875

fitted with unusual "Glastaeler" Ink Distributing Table.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

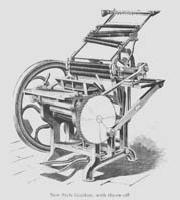

The Gordon as most people remember it.

Late model (1889) 'New Style' with throw-off.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FREDERICK O. DEGENER

The Liberty platen was invented in 1859 by Frederick Otto Degener, of New York, formerly a draughtsman for George Phineas Gordon. It was manufactured by F. M. Weiler's Liberty Machine Works (1860 - 1897) and had a mechanical action which was different from any of the other platen presses and never had any imitators. The platen had a similar motion as the Gordon platen, but the bed, in addition to being supported on legs pivoted at their lower ends, was also hinged or balanced on a shaft running through the frame behind the bed. As the platen returned to the feeding position after the impression was made, the bed not only swung backwards as on the Gordon, but also pivoted around a horizontal axis so the the face of the forme became horizontal. The rollers remained in extended vertical guides and were allowed to move vertically with the undulating action of the forme. As the bed pivoted about its axis, the disk first passed under the rollers and was followed by the type forme. A huge counter-weight was placed behind the bed which served to balance the load of the bed on its shaft. In spite of this excess movement of parts, it was reported to run easily with no more effort than needed to "pump" the Gordon. The Liberty was one of the first presses also to use an impression throw-off, originally patented in 1852 by James Young of Philadelphia. It was jokingly described 'as a machine which was half a press long when on impression and two presses long when it opened up and the forme was inked.'

Degener had a partner, compatriot, Frederick

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

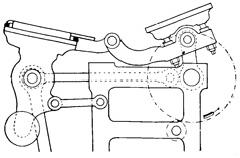

1887 Liberty Platen

Below: Drawing from patent showing the unusual pivoting motion of this press.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M. Weiler [the firm named Degener & Weiler]. Degener died in 1873 and his son, F. L. Degener succeeded him. Weiler bought out the son in 1877 and carried on the business as F. M. Weiler. About 1881 he established a factory in Berlin, Germany and the company prospered. Just the opposite happened in the US, manufacture ceasing in 1890. After that date, the Liberty's sold in the United States were imported from Germany, and were still being manufactured up to WWI.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MERRIT GALLY (1838-1910)

Merritt Gally was known to his contemp-oraries as a scientist and philosopher, because of the breadth of his inventions and their original mathematical and philosophical basis. Apprenticed to a printer at 11, he built a cylinder and a platen press while in his teens. He put himself through college and then seminary, and was ordained in 1866. But his Church career was brief, and in 1869 he set up in business to manufacture his latest platen press, (patented 1898) called The Universal.

This style of platen was known as a 'Rolling/Sliding' Platen in Australia ['Parallel Approach' in UK and USA]. The frame was massive, heavy and of one piece box con-struction incorporating a rigid vertical type bed and roller tracks. The platen rolled up from its feeding position, drawn directly by strong drawbars attached to geared crank wheels until it became vertical and about an inch (25.4 mm) from the forme. From this position it slid along polished steel slides towards the forme. Impression was regulated by eccentric bushes fitted in the platen ends of the draw bars. Fitting over these bushes were the ends of the adjuster bar/impression trip. This bar had an adjustable latch in its centre which engaged a ratchet allowing considerable adjustment.

Instead of the customary ink disk, a large drum distributor roller, fed by a ink duct to a number of distributor rollers ensured an accurate and steady supply of ink to anywhere it was needed, unlike the rather inefficient ink disk. Three or four forme rollers with riders [vibrators] supplied adequate rolling power. The press was heavier, usually a little slower, and more costly than the hinged platen, but with its superior ink distribution and positive, parallel impression, was capable of the finest platen work. The press was first manufactured by Hamilton and McNeal of Rochester, New York.

A few years before Gally's patent expired, he and his partner, Thompson had a dis-agreement resulting in Thompson redesigning the press somewhat and marketing it on his own account under the name of the Colt's Armory press. Gally's ads at the time were full

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early model Universal treadle platen

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Colts more stream-lined Armory platen

Recognised by printers and carton/ fancy box manufacturers for it's 'jobbing' versatility.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of warnings of dire trouble to buyers of the Colts press, claiming patent infringe-ment. Evidently the difficulties were either patched up or ignored, because Thompson continued with the sale of his press and Gally had the Universal made elsewhere. No new improve-ments were made to the Universal, and after Gally's death in 1910, the business was carried on as the National Machine Company. The Colts Armory press however was marketed much more energetically. A heavy duty 4 roller press, the Thomson Laureate was introduced during World War I.

In 1923, the National Machine Co. combined with the John Thompson-National Press Co.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|