|

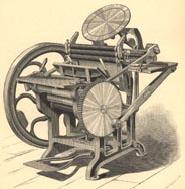

The year 1856 was another big year for Gordon, for during this period he submitted his 'alternative' Franklin Jobber, destined to become the single most famous and influential jobbing press of the nineteenth century.

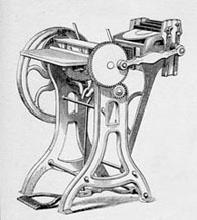

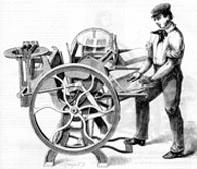

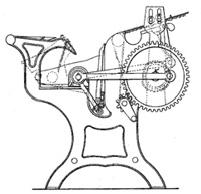

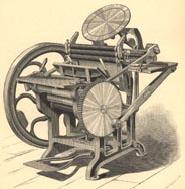

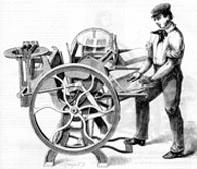

This incorporated a hinged type bed also, but he moved the hinge to the very base of the machine, maximising the radius of the arc of travel. And in place of the impression toggles, he reverted to the Ruggles system of connecting rods, attached to crank wheels mounted at both ends of a shaft. The unique rocking platen, worked from a camshaft, was tilted to align with the hinged type bed as it closed on impression. This cam action also gave additional 'dwell' [additional time] when the platen was open, allowing the operator more time to place and retrieve his/her sheets. Three forme rollers, held in saddles and mounted to spring-loaded side frames oscil-lated between ink disk and type forme and were driven by the motions of the bed.

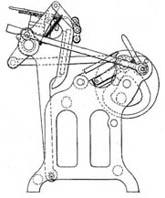

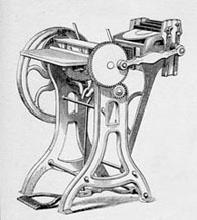

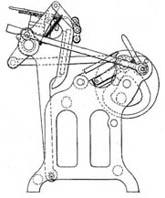

Gordon's adherence to naming several of his creations "Franklin Job and Card Presses" has caused problems to historians in obtaining a true sequential record of his prolific output. Also, it seems many of his more technically advanced designs never made it past the drawing boards or were not popular with printers of the time due, one assumes, to their "head in the sand" attitude. His "Sheet Piling Franklin, patented in 1858 seems a perfect example. Another, [patent 32,130; 1861 - shown opposite] had, in addition to an extreme rocking motion, a straight-line approach that took the platen perfectly parallel to the type bed. It also incorporated a fixed feed-board with adjustable guides mounted along the front edge. As the platen tilted back to its extremity, a set of grippers at the bottom edge of the platen gripped the sheet and held it steady during impression and delivery. This press was probably introduced to compete with Gally's popular Universal of 1859 (see following page) but evidence suggests it was not popular -- if manufactured at all! These early Franklin platens had neither impression throw-off mechanisms nor a gate to lock the platen at the point of impression, two features used in Gordon's later presses.

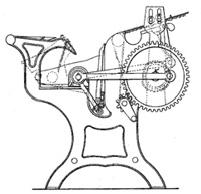

An 'improved' Franklin Jobber was displayed at the London International Exhibition, of 1862 and five years later H.S. Cropper & Co. of Nottingham, England, commenced it's manu-facture under the name 'Minerva.' Patents of the Franklin press were due to expire in 1883 enabling any competing firm to copy the design. Aware of this, Gordon conceived and introduced his Improved (or New Style) Franklin Jobber which was protected by a new - but somewhat tardy - patent No. 151,966, June 1874). This appeared in 1872. Of the same general appearance, the new version was equipped with a different mechanism for controlling the movements of the platen and bed. The platen, unlike the earlier 'rocker' was hinged under and in line with the bed, this moved through about half the distance as the original model, resulting in a reduction of power needed to drive the press, or so it was claimed. And, in place of the draw-bars and cranks, was a pair of knees, or toggles. Other improvements included an impression 'throw-off' mechanism, a handy device when running up ink or if a miss-feed occurred when feeding. Strangely, the 'new style' was not as popular as his earlier version! Fred Williams, editor-publisher, 'Type & Press' wrote in 1985; "Most printers found that the so-called improved model was actually inferior to the original machine. They claimed the platen failed to open up as far as the old jobber, resulting in feeding and make-ready problems. They also preferred the long dwell for feeding and *impression that was so characteristic of the first Franklin press. Sales of the Improved version were disappointing."

Gordon ultimately built more than 100 kinds of presses, some manufactured in Rhode Island, but most of them made later in his 1872 factory at Rahway, New Jersey. Patent office records indicate that he was granted almost 50 patents during the period from 1850 to 1875 (I have been able to locate about 35).

By 1894, when his various patents had expired, no less than eleven firms were manufacturing Gordon presses. Altogether there were eighteen different firms making 'old style' Gordons, at one time or another. Chandler & Price, who also were manu-facturing them acquired the Gordon business in 1901 along with the Gordon name.

Gordon died in 1878 at age 67. Sales of his popular presses had made him a millionaire.

* [There was no additional dwell on the impression stroke as it was crank driven]

|

|