|

MARINONI (FRANCE)

Hippolyte Auguste Marinoni (1823-1904)

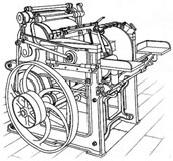

'L'Utile' Jobbber, 1879

This press appears to be a very similar machine to Gordon's 1885 New Style with throw-off (for comparison see page 89). It is highly probable as these two men had business dealings (as did Marinoni with the American press builder, Hoe) so it might have been built under licence or alternatively fully imported form the USA and re-badged.

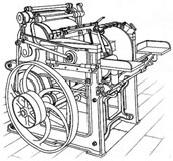

THE PROUTY PRESS CO. (USA)

The Prouty Job Press, 1881 »

George G. Prouty was another prolific designer of both platen and cylinder presses.

This clamshell platen had a rigid bed with an oscillating platen hinged at its base to a set of supporting/forwarding arms oprtating from within the frame and worked by a cam. Conventional crank action pulled the platen upright and onto the type bed.

P. J. JENNINGS (USA)

Patent No. ?? 1882 »

The Dauntless Job Press was a conventional, robust clam-shell platen. It comprised a rigid bed with an oscillating platen hinged just beneath the bed to a set of draw-bars connected via a crank. The top roller (and trucks) appear smaller than the other two, indicating it distributed the ink only, but never touched the forme. This model had no impression throw-off although later models were so equipped.

W. A. KELSEY & CO. (USA)

Excelsior Rotary Job Press, 1882 »

The term 'Rotary' was used by other makers also, and really quite confusing; it indicated flywheel motion only (but 99% of platens had them!). The machine was a basic clamshell type, hinged below the platen, the oscillating platen powered by a toggle arrangement. It was fitted with an automatic Card Dropper attachment (or Kicker) consisting of adjust-able brass gauges which 'tripped' (lifted) after each impression, dropping the card into a delivery tray beneath the platen.

GLOBE MANUFACTURING CO., (USA)

Patent No. ??; 1885 »

The Clipper was another conventional clam-shell platen. It comprised a rigid bed with an oscillating platen hinged just beneath the bed to a set of draw-bars connected via a crank. This cut shows the 8" x 12" model, a smaller 7" x 11" was also manufactured. For such a small machine it's surprising that it was equipped with three forme rollers.

After 1889 this press was manufactured by J.M. Jones, of Palmyra, New York.

GODFREY'S GRIPPER PRESS (UK)

USA Patent No. 344,265; 1886 »

Alfred Godfrey had this press registered in the UK, France and Belgium also. Another of the 'flattened cylinder' type. Sheets were fed to a stationery feedboard and registered, taken by revolving grippers to the platen, printed and moved on to a delivery tray. It was manufactured by Furnival & Co. of Leeds, UK.

JOHNSON-PEERLESS WORKS (USA)

Manufactured 1886 to 1898 »

Another close copy of George Gordon's popular 'Old Style' Jobber, manufactured after his patent had expired. These type of platens eventually became an indispensible part of printers' equipment Altogether there were eighteen different firms making 'old style' Gordon platens at one time or another.

Johnson-Peerless Works were situated at Palmyra, New York.

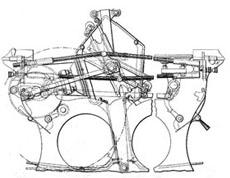

F. HARRILD & J. BUCKLAND (UK)

Patent No 13,006 - 31/7/1891 (UK)

Patent No. 517,040 27/3/1894 (USA)

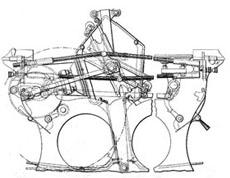

Harrild's Double Platen »

This was a platen press having two type beds set back to back in an oscillating frame and two rocking platens situated opposite the two type beds, the operation being such that while the one platen was moving away from its corresponding bed after having received impression, the other platen was moving towards its bed to receive impression. A feature of this press was the rollers, impression control and the impression 'throw-off' (of either side) could be altered independently of the other.

|

|