|

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * 'By 1830 the brothers Isaac and Seth Adams, who had been manufacturing iron hand presses, went over to the 'bed and platen'. Their basic conception remained popular for more than fifty years. Originally the press was made principally of wood, and was driven by man-power, but the Adams brothers later substituted iron parts and steam-driven equipment'. (Printing Presses: History and Development from the Fifteenth Century to Modern Times, by James Moran, 1973)

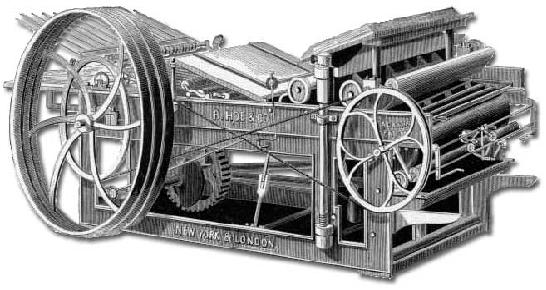

'In these machines, the type is placed upon an iron bed, after the usual manner of the hand press, and this bed is raised and lowered by straightening and bending a toggle joint by means of a cam, thus giving the impression upon the iron platen fixed above it, and firmly held in position by upright iron rods secured to the bottom-bar, a strong cross-piece, at the base of the machine. The ink fountain is at one end of the press; the inking rollers travel twice over the forme, in a movable frisket frame, while the bed is down; the paper is taken in by grippers on the frisket and carried over the forme, when the bed rises and the impression is given; and finally the sheets pass forward from the frisket by tapes to a sheet flier, which delivers them on the fly board. Although many of these machines were made and great numbers are still used, and notwithstanding the fact that it was thought by many experienced printers that fine book and cut work could be done in no other way than by flat pressure, this system of printing has given place to that of the cylinder press.' (A Short History of The Printing Press and of the Improvements in Printing Machinery from the Time of Gutenberg up to the Present Day', published by Robert Hoe in 1902.

'Machines of this principle have long been discarded for those of the cylindrical character, but they were capable of turning out fairly good bookwork. Their great drawbacks were their slowness of production and their inferiority in inking facilities compared with the more modern make of cylinder machines.' Printing: A Practical Treatise on the Art of Printing, published by Charles T. Jacobi, London, 1919.

In 1865, The U.S. Government Printing Office added 12 first-class Adams presses, manufactured by Hoe & Co. (at a cost of $36,000) to the existing 23 purchased in 1861, the year the GPO was inaugurated.

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

|

|