|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THE JOBBING PLATEN

History and Development

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The early 19th century saw the beginning of enormous changes in printing, for during what is generally regarded as the second phase of the industrial revolution (1800-1850), printing became one of the first industries to utilise automation. Various problems had to be solved before the partially mechanised handicraft could be transformed into a high-output factory operation. The early 'flat-surface' inventors of this period, Stanhope, Koenig, Clymer, Treadwell, Napier and others made significant improvements to machinery involved mainly with the newspaper and book printing industry. It is generally agreed that the press that revolutionised job printing, that is, the printing of handbills, cards and stationery, was the treadle-powered, self-inking platen, first produced in Boston, U.S.A. by Stephen P. Ruggles in 1851. This was his small 'Card & Billhead' press and it was reputed to be the first commercially successful platen with a near-vertical bed and a hinged platen. However, fellow Bostonian, Daniel Treadwell took out a patent for a 'platen press' worked appropriately, by a treadle some 30 years earlier! Although somewhat primitive, it incorporated novel mechanical ideas which 'sowed the seeds' for later inventors. Another, Englishman John Kitchen, a printer from Newcastle on Tyne, took out a patent in 1834 for a clamshell platen, possibly the very first, and although not manufactured, was years ahead of its time . . . and sadly overlooked by historians! Many patents were granted for platen jobbers in these early years of its development; a notable number of them, in the USA, going to George P. Gordon, printer, inventor and manufacturer of prodigious energy.

Here then, in attempted chronological format, the evolution of the incredible little 'snapper'!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DEFINITION OF SOME TECHNICAL TERMS USED IN THIS ARTICLE

CLAMSHELL PLATEN -- Contentious term among technical writers past and present! Some refer to ALL platen presses having type-bed and platen hinged together, regardless of make. Others see the need to differentiate between 'Gordon 'old style' platen types, because of the rocking platen -- they are still hinged regardless! However, for the purpose of this article I have gone with the latter to avoid too much confusion.

MACHINE or PRESS -- Americans seemingly refer to all printing machines, powered or not, as presses, whereas their British counterparts use this term when the press is powered by either human, animal or mechanical methods. I use both when it suits.

OSCILLATE -- A regulated movement to and fro between two points -- like a pendulum, either 'front-on' (e.g. platen or type-bed) or 'side-on' (e.g. distributor rollers and riders).

ROCKER, ROLLING -- Object that oscillates about axis without making a complete revolution. (For example a platen or a duct transfer roller).

ROLLING/SLIDING or PARALLEL APPROACH -- Refers to the motion of the platen 'sliding' up on guide rails parallel to the forme, impressing, sliding back and rolling open via a cam.

TOGGLE -- Two plates or rods hinged together end-wise, so that force applied at the elbow to straighten the joint is transmitted to the outer end of one or each plate or rod.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DANIEL TREADWELL (1791-1872)

Having studied anatomy with the intention of becoming a physician, Treadwell learned that the muscles in the leg were more powerful than those of the arm and decided to put this principle to the test. "After some deliberation, I selected the printing press, as connected to one of our most useful arts." His locally-made 'foot press' generated some interest but only a small number were actually sold. The ambitious Treadwell, however decided to try his luck in England, He patented his press and contracted with Scot, David Napier to build it. According to Hansard, only one press was built, due to lack of interest from the London printers and hostility from the workers there.

While the idea of a hinged platen and the treadle operation provided elements for later jobbing presses, Treadwell proposed nothing new in the manner of inking, persisting with the time-honored hand inking roller, and continued to use the traditional frisket, albeit a novel revolving one. He eventually retired his 'foot-press' and developed the 'bed & platen' press (see index), the first built in 1821. This incorporated a rotating ink disc which, interestingly, was used extensively on many later American jobber presses. Treadwell even-tually disposed of his printing interests and in 1835 became a professor at Harvard University.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JOHN KITCHEN (1804-1852)

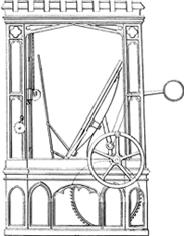

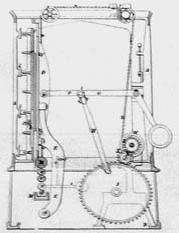

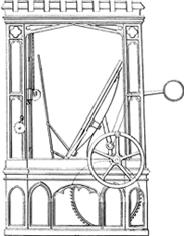

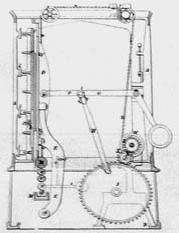

Author, James Moran, in his article on 'The Jobbing Platen' has little to say about this fellow - probably due to the inventor's inability to have his press manufactured. However, it is interesting to examine his patent and drawings of 1833, as the method of obtaining impression shows a close resemblance to later, simple clam-shell platens, especially in the manner in which the platen is hinged to the bed and the use of 'jointed levers' actuated by a crank and connecting rod. Moran states 'compared with the eventual jobbing platen it was a complicated piece of mechanism etc,'

|

|

|

|

|

|

|

|

|

|

|

|

|

On the contrary, the drawings (below) show a rather simple mechanism although the frame, is described as 'reminiscent of a piece of church furnishing'. One should remember also that this design was created 18 years before Ruggle's famed Card & Billhead Press, which is regarded by experts as the very first 'clam-shell' or hinged platen.

Kitchen eventually emigrated to Australia in 1839, records indicating that he applied for positions at Government Printing Offices in NSW, Victoria and Tasmania. It is also thought he was New Zealand's first printer.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Kitchen's Patent No. 6454.

LEFT: Showing toggle joint (jointed levers) fully extended with platen on impression. Note the hinge mounted at floor level. Ink duct (below platen) was encased with a water jacket to keep ink at constant temperature. This supplied ink to distributor rollers above which in turn transferred ink to the one large forme roller, activated by a cable and pulley arrangement.

RIGHT: Platen and frisket bars open, roller descending over forme. Sheets were intended to be fed in and delivered from the side!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|