|

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

On the 5th May, 1845 the above company delivered its first high-speed printing press 'of the late design' to Hartmann's printing office in Augsburg. This date marks the beginning of the eventful history of printing press construction at M.A.N., the only branch of the company's activities that can claim an unbroken line of development from 1845 to the present day.

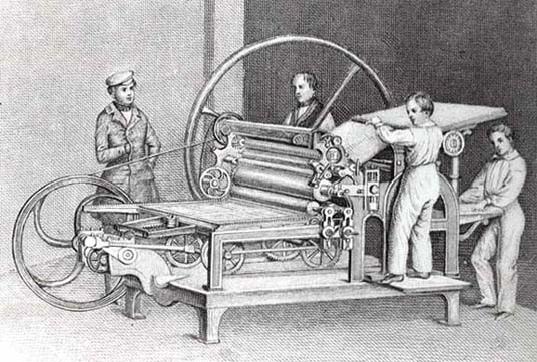

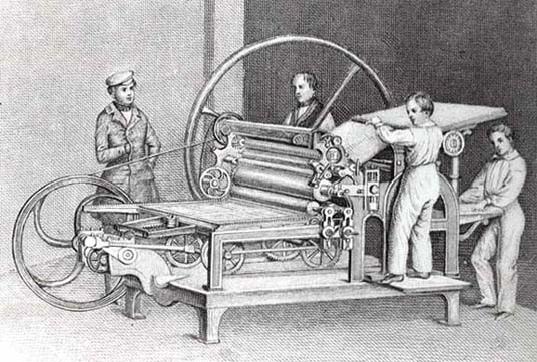

This was a single cylinder hand-powered and hand-fed stop-cylinder press, built according to the plans and under the supervision of Carl August Reichenbach, (1801-1883) a nephew of Frederick Koenig (see index). Reichenbach and his brother-in-law and business partner, Carl Buz, (1803-1870), a prominent civil engineer, initially leased the Augsburg firm of Sander'sche Maschinenfabrik in 1840. An advertisement from October, 1844 describes the extensive range of products offered - steam engines, steam boilers, hydraulic engines, pumps, transmissions and so on. Especially mentioned was the manufacture of printing presses and 'qualification' for operation.

At the start, Reichenbach's main aim was to improve the crank drive motion. As a completely new component, he introduced a 'wagon' that traversed back and forwards on four wheels such as used for railway wagons [size '2' had six wheels] and this functioned as a drive as well as a carrier for the bed of the press. These geared bed wheels rolled on two geared rails anchored to the base of the press and meshed with corresponding gear racks mounted underneath the bed. Other improvements included a more precise inking arrangement and superior impression cylinder mountings. The design was more compact than other types and was especially advantageous for larger paper sizes. It remained part of the production range until 1889.

Reichenbach's press was very simple, required a minimum of energy, was low wearing and had the great advantage of being extremely reliable. Other manufacturer's soon adopted this principle as patent protection in Bavaria then was 'full of loopholes'. [It was only in 1883 that the International Convention of Paris provided a more effective protection for copyrights and patents]. Incredibly, in the space of eight months - from starting production to delivering the first press, he delivered a sound, commercially viable product. The price for this first press including installation and twenty five lengths of cleaning cloths totalled 2,811 Gulden and 24 Kreuzer. (Daily wage for a fitter or caster amounted to one Gulden and 36 Kreuzer, for a 68 hour working week!)

The first Augsburg double-cylinder press, i.e. a machine with two impression cylinders working from a common forme, was delivered in 1850. This enabled production to be increased to 3,000 sheets per hour. Presses for larger paper sizes were also built, both single and double-cylinder designs. These double-cylinder presses were particularly popular with newspaper printers up until the time the rotary press was introduced in the 1870's.

In 1857, due to increasing orders and a shortage of working capital the business became a limited company bearing the name Maschinenfabrik Augsburg.

Many thanks to Gabriele Mierzwa, Museum and Historic Archives, M.A.N Roland

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

|

|