|

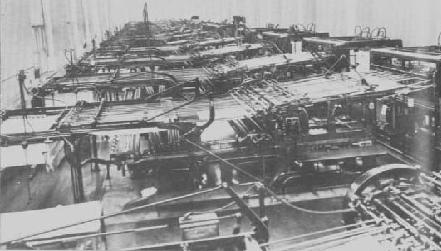

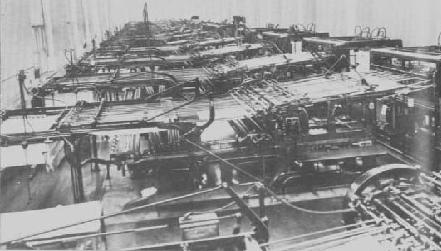

Two-Revolution Presses

Drive and Bed Motion (for most types)

The principle of the two-revolution is that the cylinder continually rotates in the same direction, twice for each one copy produced. On the first cycle, the grippers snatch the sheet from the guides, the cylinder drops onto the bed bearers, the sheet is printed and returns back to the top of the cylinder. At the beginning of the second cycle, the type carriage is returning, the cylinder is raised to clear the gear rack/type forme and the printed sheet is being released by the grippers and directed onto the delivery system. Unlike Stop-Cylinder presses the propulsion of the type carriage is caused by a continuous driving gear driving intermittently between a top and bottom traverse rack, the reversal mechanism being aided by either steel springs (early models) or air buffers (later models). The ubiquitous Miehle is probably the best known press of this kind, originating in the USA, being built both there and in the U.K.

Preparing the Miehle

1._Oil, grease, clean and check (there are approx 250 oiling points!)

2._Dress the cylinder correctly, packing thickness is .055'' which includes a sheet of the job. A micrometer, correctly adjusted is indispensable for this purpose.

3._Select near or off lay and position the sheet as near as possible to the centre with a gripper near each end of the sheet. If hand-feeding it is advisable to place the sheet in a comfortable position nearer to the operator.

4._Lower the delivery board and run a sheet around the cylinder. Stop the machine with the sheet in the grippers and check for a parallel grip of approx. 18 points. Continue the sheet down the delivery, check and set the joggers.

5. Clean the back of the forme with a steel rule, position the forme on the bed, check all blocks for correct height, plane down and tighten quoins.

6._Make certain the delivery frame is disconnected then raise it to access rollers.

7._Lock rollers in their correct position and run up colour. Lower the delivery frame.

8._Take proofs to find exact position, obtain OK, insert a lay mark if possible and proceed to makeready.

9._Place ink in fountain and pre-set to job.

Start the feeder and run several sheets through twice to check registration.

Feed-board and Lay-Tongue settings

When adjusting the feed-board and the lay-tongues to the cylinder, the cylinder must be fully lifted, correctly packed and the lay-tongues positioned clear of the grippers and the shoo-flys.

The feed-board and the lay-tongues are adjusted in conjunction with each other. They should be set so that the lay-tongues are either tangental to or else to conform to the curve of the cylinder with a clearance of approx. 2 points. The feed side and the gear side of the board and both lay-tongues must be set identically.

When completed, check to see if the feed-board adjusting screws are in a position so that the feed-board can be both raised or lowered. If the adjustings do not allow this then the tongues will have to be bent so that they can. After adjusting the tongues make certain they hold rigid on the slide bar. If they move too freely, they may move whilst the press is running, thereby altering the feed-board setting and also cause damage by fouling the grippers.

|

|