|

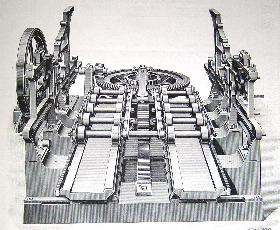

Setting the Cylinder

The test for need of adjustment

1. Remove bed bearers, clear throughout and then check for correct height .917'' Clean cylinder bearers and the bed, then replace bed bearers.

2.BPlace a strip of tissue on each bed bearer and turn the machine to impression. If the tissue can be removed, then the cylinder needs further adjustment.

Method of adjustment

1._Make sure there is a gap between the cylinder bearings.

2._Loosen the cylinder adjusting screw.

3._Place strips of tissue between cylinder and bed bearers, then adjust the cylinder by means of the cylinder impression screws so that the strips are held firmly.

4._Place a medium sized forme on the machine and with the machine on impression test again to see that the strips are firmly held. If not, the impression screws must be tightened further.

Difficulties on a Cylinder machine

A slur is a blurred or thickened impression caused by false movements between the forme and paper. Some causes of slurring are:

* Loose or baggy packing.

* Cylinder over or under packed.

* Sagging of the sheet before it reaches the forme or sagging in the gutters.

* Grippers incorrectly adjusted.

* Insufficient grip.

* Wear in the machine.

* Loose plate, springy forme or warped mount.

* Oil on the bearers.

* Plates not type high.

* Card which is too stiff.

* Vibration of the machine.

Roller wipes are caused by:

* The forme not type high.

* Unsuitable ink.

* Incorrectly set rollers.

* Faulty rollers.

Bad register is usually caused by:

* Careless feeding.

* Loose feed-board or lays.

* Incorrect grip or loose grippers.

* Wear in the machine or sprung forme.

* Incorrect adjustment of pushrod.

Packing

A packing or dressing is necessary on all machines to provide a resilient surface for applying the impression, to enable the impression to be regulated for all thicknesses and surfaces of stock and to provide a place for makeready. To obtain a clear sharp impression, the cylinder must neither be under or over packed and the packing should be of an even thickness throughout. A hard packing, though requiring a more careful makeready, is superior to a soft packing for a good sharp impression. On all cylinder machines, the body of the cylinder is below the cylinder bearers. The depth of this undercut must be ascertained to be able to correctly pack the cylinder.

Packings to suit these various depths are made up of two parts, the permanent packing and the job packing. The job packing should be approximately .030" as this will allow for the the regulating of impression for the average thickness of stock encountered. The suggested packing for a machine requiring .055" is: permanent packing - 4 oiled manillas at .006", job packing - 5 super cals at .003", two manillas at .006" plus sheet of stock to be printed .004" = .055". When two or more manillas are used for the permanent packing a thinner harder material of equivalent thickness may be used. Materials such as System board, Manilla board, Elephantide etc, make suitable permanent packings. It is a good idea to write on the top sheet of a permanent packing the thickness to avoid mishaps.

Adjustment and care of the ink fountain

1. Always adjust out from the centre key.

2. Adjust fountain when revolving machine/duct at machine speed.

3. When replacing blade, push firmly home to original position.

4. Avoid damage to the edge of the blade.

5. The blade, adjusting screws and fountain ends must be kept free from dried ink.

6. Lubricate fountain bearings and end of fountain cylinder regularly.

7. If ink is not being used for the full length of the fountain, avoid doing the screws up tightly. Use clumps to keep the ink in necessary position.

8. Avoid scoring fountain cylinder by keeping the fountain free from dust and grit.

9. Always use a long sweep and a finer setting of colour in preference to a short sweep and a heavy amount of colour.

* * *

|

|