|

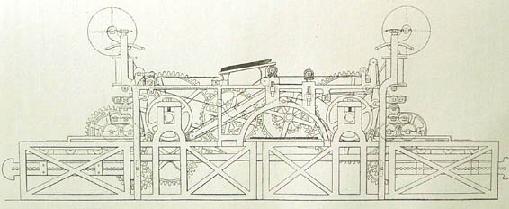

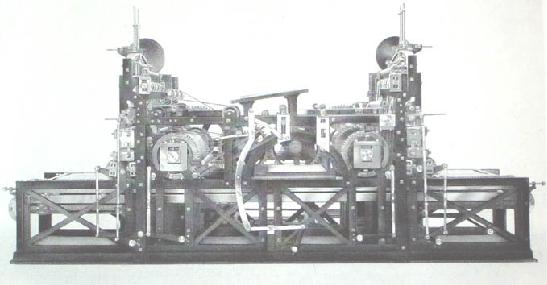

__'An engraving of this machine is shown above. A view will teach us, that it is a combination of two machines into one. It contains accordingly two formes, two printing cylinders, two inking apparatus, but only one feeder, and in place of the second the above mentioned register apparatus, inserted between both printing cylinders. The first (white printing) forme lies upon the coffin of the machine to the left, the second (reiteration) [back-up] forme upon the coffin of the machine to the right. The inking apparatus, the coffins and the printing cylinders as likewise the register apparatus are in continual motion, the feeder however is put into motion for each single sheet by the wheel-work, (diagram below) and in the same way it is brought to rest again.. Upon each printing cylinder there is only one place of the size of the sheet covered with printing cloth [cylinder packing]; therefore the forme may return freely under that part of the circumference which is not covered. The formes however are blackened at each passing beneath their inking cylinder. When therefore a sheet of paper on the feeder, while it is in a state of repose, is put upon the marks and the apparatus is set to move; then the paper is carried, between two rows of tapes (which we call inner and outer friskets) and by these put round the first printing cylinder. Here the paper meets with the forme already blackened and is printed on one side. The inner frisket, which, here lies between the printing cylinder and the paper, takes the paper from off the printing cylinder and is laid itself together with this and with the outer frisket upon the register apparatus, which sustains the paper till it is arrived in a vertical position over the second printing cylinder. Then the sheet is kept fast between the two friskets, put round the second cylinder (to the right) and, there meeting with the second forme, it is printed on the other side. It will be clearly understood, that the sheet has turned round on its course only by the form of this course -- being an "S" -- and that by this contrivance the outer frisket has been turned to an inner one, which inner frisket now takes the sheet from off the second printing cylinder, putting it, printed on both sides, upon the board in the middle of the machine. The friskets afterwards return, conducted by cylinders and rolls, into their principle condition.

|

|